Laser cutters leave an aesthetically pleasing finish so usually no post processing is necessary.

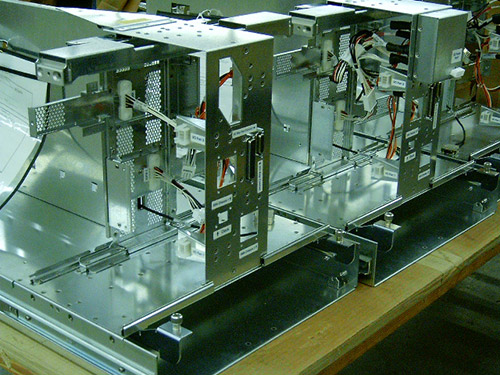

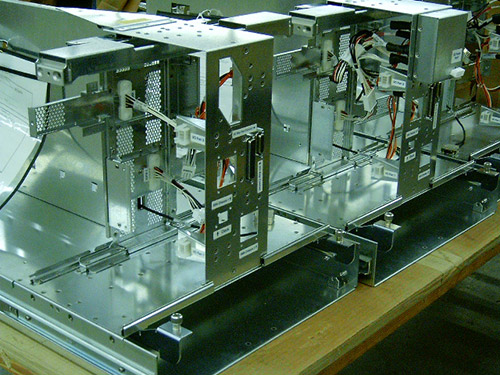

Bend lance sheet metal laser cut.

A 1 degree tolerance on all bend angles.

Aaa laser cut cc offer sheet metal laser cutting and manufacturing light and medium fabrication structural steelwork and light medium engineering services in johannesburg.

We can help you build any kind of processing equipment or even packaging machinery.

We cut bend weld metal sheet for you.

We also offer bending rolling welding in house polishing and brushing.

The sides of the bridge lance are open for example.

Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Bends in sheet metal are manufactured using sheet metal brakes.

While creating the forming tool model the cad jockey defines a stopping face.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material.

The automated cutting processes guarantee high precision and quality of ready parts.

Laser cutters are mainly used to cut through sheets of metal wood cardboard or plastic.

If you have any specifications please add them to the commentary section.

The minimum distance between two counterbores is eight times the material thickness.

Avoid large sheet metal parts with small bent flanges.

Sheet metal fabrication aluminium steel.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm.

We are the experts when it comes to laser cutting and sheet metal fabrication.

We provide metal cutting services for the fabrication of parts out of sheet metal.

The forming tool.

We are specialists in laser profile and plasma cutting.

We use technologies as cnc laser cutting and cnc bending.

It helps to bend and crease a piece of sheet metal and even create a box type form.

Design for manufacturability sheet metal guidelines bends for the ease of manufacturing multiple bends on the same plane should occur in the same direction.

Additionally cut instead of stretch can be specified to create openings.

Manufacturers use this technique during the sheet metal prototyping process.

Avoid large sheet metal parts with small bent flanges.

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger counterbores.

Typically used in 2d designs tracing a path onto a sheet to cut out forms.